Understanding Separators in Auto Parts and Supplies

In the world of auto parts and supplies, the term "separator" plays an integral role. Whether you're engrossed in auto repair or auto detailing, understanding the various applications and functions related to separators can dramatically enhance your efficiency and resourcefulness. This article delves deep into the significance of separators within the automotive industry, breaking down how they affect everything from maintenance to repair practices.

The Role of Separators in Automotive Components

Separators serve as vital components in numerous automotive applications. In essence, a separator's primary function is to divide different elements or materials, ensuring optimal performance and safety. Below are some essential areas where separators are commonly employed:

- Fluid Management - In engines and transmission systems, separators help manage various fluids by keeping them distinct, preventing contamination, and ensuring efficient fluid flow.

- Part Assembly - During the assembly of various components, separators can be used to prevent unnecessary contact and damage between parts, maintaining the integrity of delicate components.

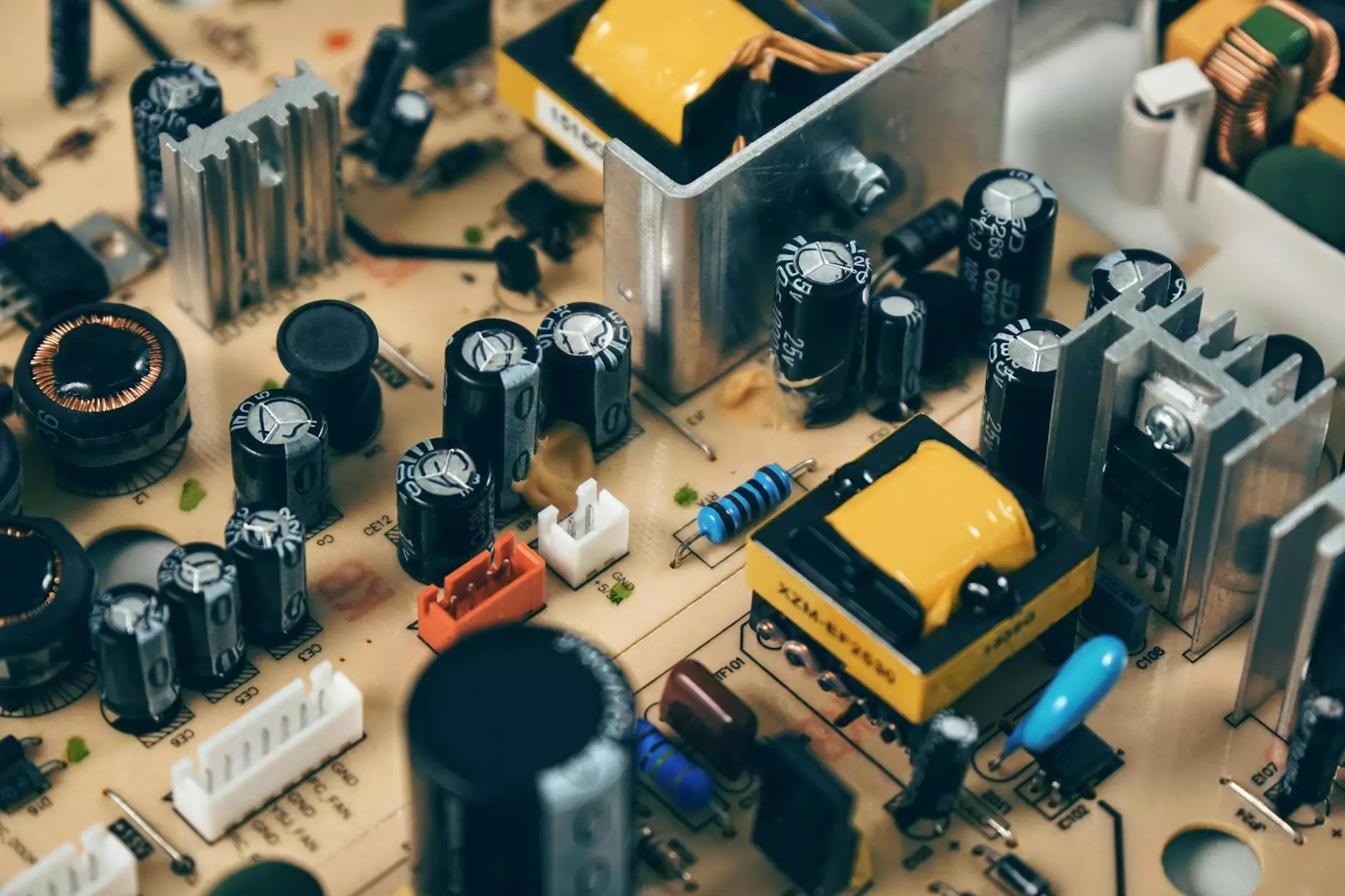

- Electrical Systems - In automotive electrical systems, separators play a crucial role by isolating electrical circuits, minimizing the risk of short circuits, and ensuring reliable performance.

Types of Separators in Auto Parts

Separators come in various forms, each adapted for specific applications within the automotive industry. Let's explore some common types:

1. Oil Separators

Oil separators are crucial in engines and compressors. They separate oil from gas or vapor, ensuring that only the necessary amount of oil circulates. This helps maintain engine efficiency and longevity by preventing excessive oil consumption and reducing emissions.

2. Fuel Separators

Fuel separators are essential for removing water and impurities from fuel. They help keep fuel systems clean, which is vital for optimal engine performance. Contaminated fuel can lead to clogging and poor engine performance, making fuel separators a key component in any auto repair toolkit.

3. Air Separators

In cooling systems, air separators prevent air from entering the coolant liquid, ensuring proper heat transfer and engine cooling. This type of separator is critical to maintaining engine temperatures, especially during heavy load conditions.

Why Are Separators Important in Auto Repair?

For automotive technicians, understanding the significance of separators can facilitate better repair practices. Here are several reasons why separators are indispensable:

- Enhanced Efficiency - Proper use of separators can streamline repair processes by ensuring that components operate effectively without interference from unwanted materials.

- Cost Savings - By preventing component damage through effective separation, automotive professionals can save on replacement costs and reduce downtime associated with repairs.

- Improved Safety - Separators help maintain safe operating conditions by ensuring components function as intended, thus reducing the risk of accidents related to component failures.

Integrating Separators into Auto Detailing Practices

In the domain of auto detailing, separators also play a pivotal role. Detailing involves thorough cleaning and conditioning of a vehicle’s interior and exterior, and effective use of separators can enhance these efforts significantly.

1. Chemical Separators

When using various cleaning and detailing chemicals, it's crucial to keep them separated to prevent chemical reactions that can lead to ineffective cleaning or damage to surfaces. Chemical separators are used to store different products securely, maximizing their efficacy and safety.

2. Part Separators in Organization

Detailers often utilize part separators for organizing tools and products. This organizational technique boosts efficiency and ensures that every tool is easily accessible, which can significantly reduce the time taken for detailing a vehicle.

Best Practices for Maintaining Separators in Auto Parts

To ensure that separators function optimally, it's important to adhere to several best practices:

1. Regular Inspections

Always inspect separators for wear and tear. Replacing worn or damaged separators can prevent costly repairs down the line.

2. Keeping Components Clean

Maintaining cleanliness around separators is crucial. Accumulated dirt and debris can affect their efficiency, so regular cleaning is necessary.

3. Using Quality Parts

Always use high-quality separators that match or exceed OEM specifications. This ensures reliability and performance in any automotive application.

Conclusion

In summary, the term separator holds substantial relevance in the realm of auto parts and supplies, auto repair, and auto detailing. By understanding the various applications and types of separators, both automotive professionals and car enthusiasts can improve their practices, enhance vehicle performance, and ensure safety. The right separators not only contribute to effective operations but also play a critical role in the longevity and reliability of vehicles.

Whether you are handling auto repair or engaging in detailing practices, incorporating quality separators is essential. Explore further by visiting attotrafic.ro for top-notch auto parts and supplies tailored to meet your needs.