Understanding Diesel Engine Valves: Key Components for Performance

The diesel engine is a marvel of modern engineering, renowned for its durability and efficiency. At the heart of this complex machine lies a crucial component: the diesel engine valve. This article dives deep into the world of diesel engine valves, exploring their significance, types, functioning, maintenance tips, and how they contribute to the overall performance of diesel engines.

The Critical Role of Diesel Engine Valves

Diesel engine valves are pivotal in controlling the flow of air and fuel into the combustion chamber and the exhaust gases out. Without these valves functioning correctly, the entire engine operation can be compromised, affecting efficiency and performance. Understanding the role of these valves goes beyond just knowing their location; it involves grasping how they influence various aspects of engine operation, including:

- Air Intake: Diesel engine valves ensure that the right amount of air enters the combustion chamber, crucial for combustion efficiency.

- Exhaust Flow: They also facilitate the timely expulsion of exhaust gases, preventing back pressure that can harm performance.

- Compression Ratio: Valves affect the engine's compression ratio, which is pivotal for achieving higher torque and power.

Types of Diesel Engine Valves

Understanding the different types of diesel engine valves is essential for mechanics and diesel engine enthusiasts alike. The major types include:

1. Intake Valves

Intake valves are responsible for allowing air (and fuel in some cases) into the cylinder. These valves must open at the correct time during the engine’s cycle to maximize airflow and optimize performance. Typically, intake valves are larger than exhaust valves to permit a more significant amount of airflow.

2. Exhaust Valves

Exhaust valves function to release the combustion gases from the cylinder after the power stroke. They are usually designed to withstand higher temperatures due to the hot gases they expel, requiring materials that offer excellent heat resistance and strength.

3. Safety Valves

Safety valves play a crucial role in maintaining optimal pressure levels within the engine. If pressure exceeds safe limits, these valves open to release excess pressure, thus preventing potential engine damage.

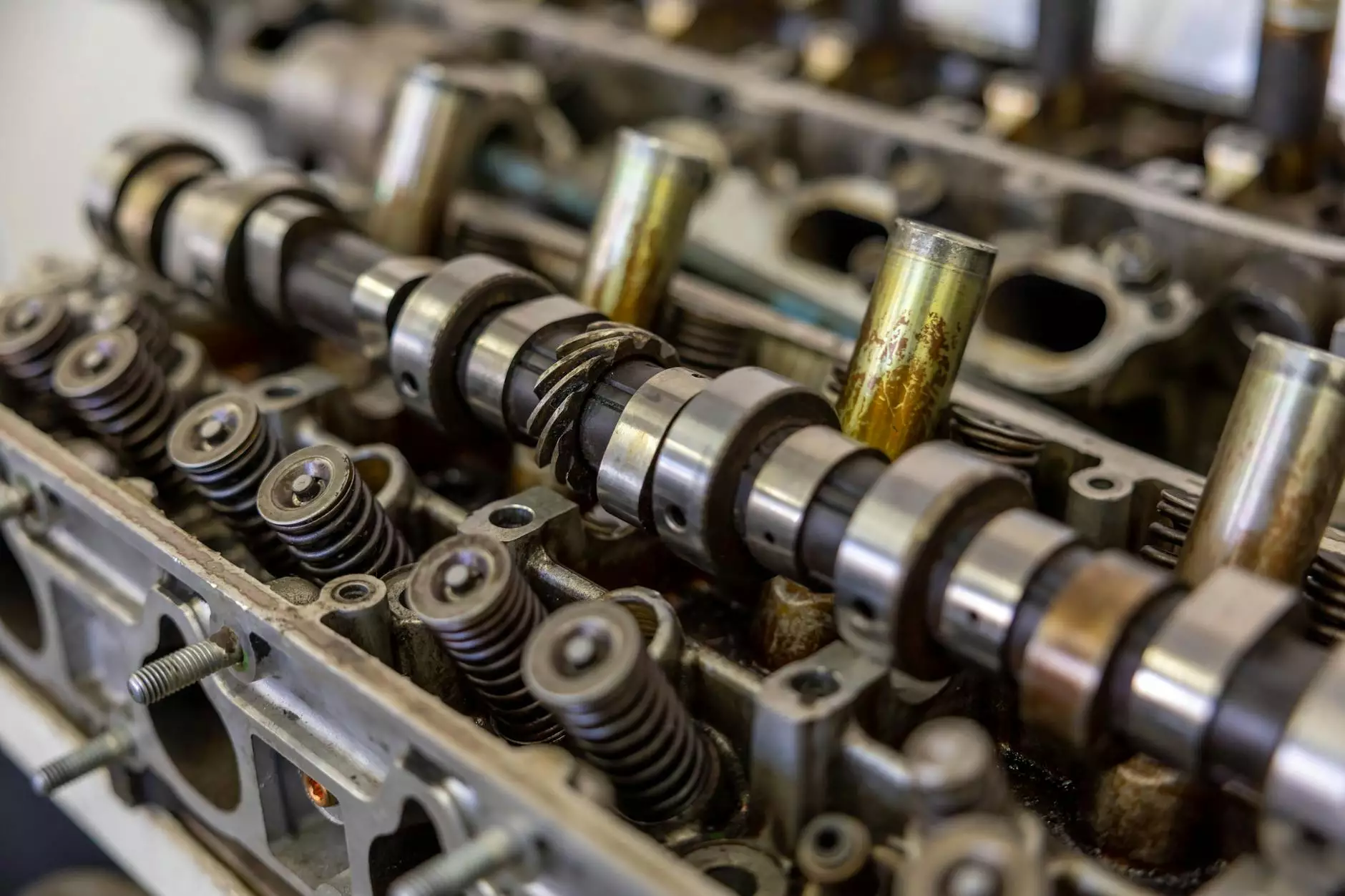

The Mechanism of Diesel Engine Valves

The operation of diesel engine valves is governed by several components, including camshafts, pushrods, and rocker arms. The following explains how these components work together to ensure valves operate smoothly:

- Camshafts: These play a pivotal role in opening and closing the valves at precise intervals dictated by the engine’s firing sequence.

- Pushrods: They relay the movement initiated by the camshaft to the rocker arms, enabling the opening and closing of the valves.

- Rocker Arms: These leverage the movement from the pushrods to directly open the valves, timing their operation meticulously to sync with the engine’s cycle.

Maintenance of Diesel Engine Valves

Regular maintenance is vital for the longevity and optimal functioning of diesel engine valves. Here are key maintenance practices:

1. Regular Inspections

Frequent inspections can help identify early signs of wear and tear, such as scoring on the valve surfaces or burning around the edges. Addressing these issues early can prevent more severe problems down the line.

2. Valve Adjustments

Over time, diesel engine valves can go out of adjustment, leading to poor performance. It’s advisable to check and adjust valve clearance regularly to ensure they operate effectively.

3. Timing Belt and Chain Maintenance

A well-timed engine is crucial for valve operation. Regularly check the timing belts and chains to ensure they’re in good condition and properly tensioned.

4. Use Quality Replacement Parts

When valve replacement is necessary, sourcing high-quality diesel engine parts from reputable suppliers is essential. This ensures compatibility and enhances performance, thereby extending the engine lifespan.

Common Issues with Diesel Engine Valves

Despite proper maintenance, issues can still arise with diesel engine valves. Common problems include:

1. Valve Wear

Over time, the constant opening and closing can lead to wear, particularly on the valve seats. This can lead to misfiring, reduced power, and increased emissions.

2. Carbon Buildup

Carbon deposits can accumulate on the valves, leading to improper sealing. This can cause compression losses and reduced engine efficiency.

3. Valve Sealing Issues

If valves do not seal properly, it may result in overheating, poor fuel efficiency, and a notable drop in engine performance.

Finding Quality Diesel Engine Parts Suppliers

When it comes to sourcing diesel engine valves and other critical components, choosing the right supplier matters significantly. Here are some tips for finding reliable suppliers:

- Reputation: Look for suppliers with a strong industry reputation, like client-diesel.com, known for quality and reliability.

- Product Range: Opt for suppliers offering a wide range of parts and solutions, ensuring you can get everything from valves to complete engine kits.

- Customer Service: Reliable suppliers should offer excellent customer service, providing support in choosing the right components for your needs.

- Warranty: A good supplier will offer a warranty for their products, ensuring you have protection in case of defects.

Conclusion

In conclusion, diesel engine valves are indispensable components that play vital roles in engine performance and efficiency. Understanding their types, mechanisms, maintenance tips, and potential issues can significantly enhance your ability to maintain and optimize your diesel engine.

When searching for high-quality diesel engine parts, remember to consider trusted suppliers like client-diesel.com. By ensuring you have quality components and conducting regular maintenance, you can maximize your engine's lifespan and functionality.

Further Reading

For those passionate about diesel engines, consider exploring more about topics like engine tuning, fuel injection systems, and aftermarket exhausts. Each of these areas can contribute to improved performance and efficiency of your diesel engine.